OUR TECHNOLOGY

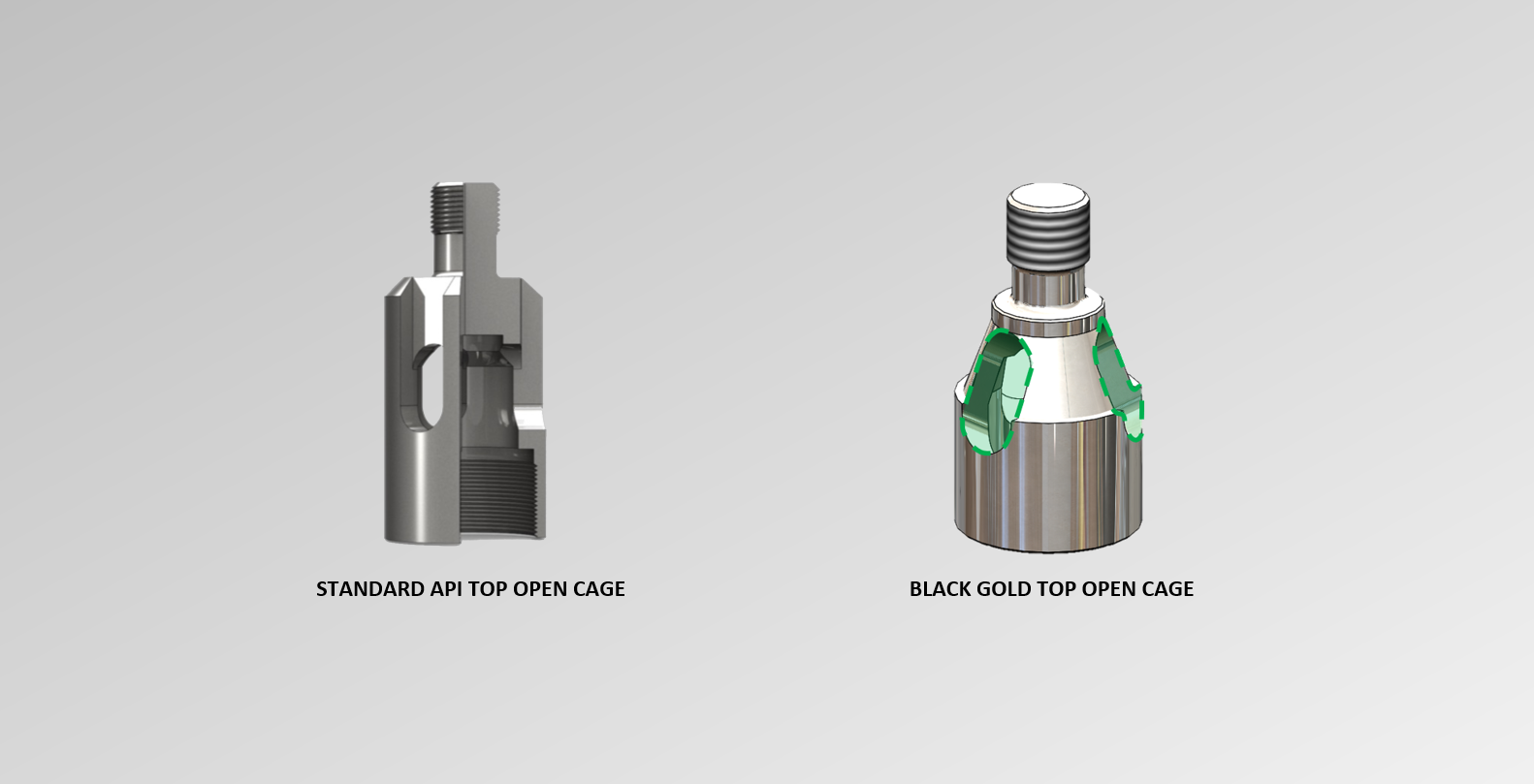

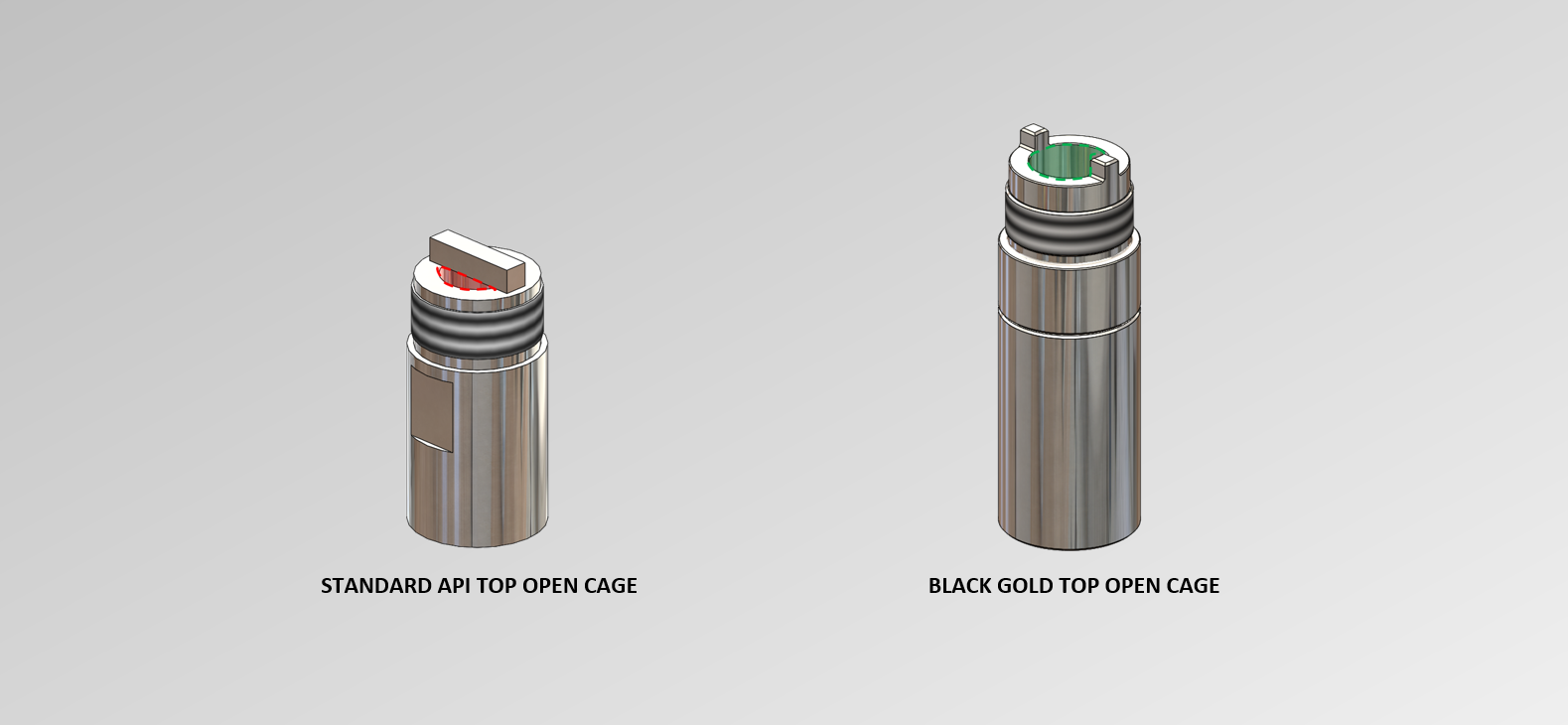

- High Flow Top Open Cages

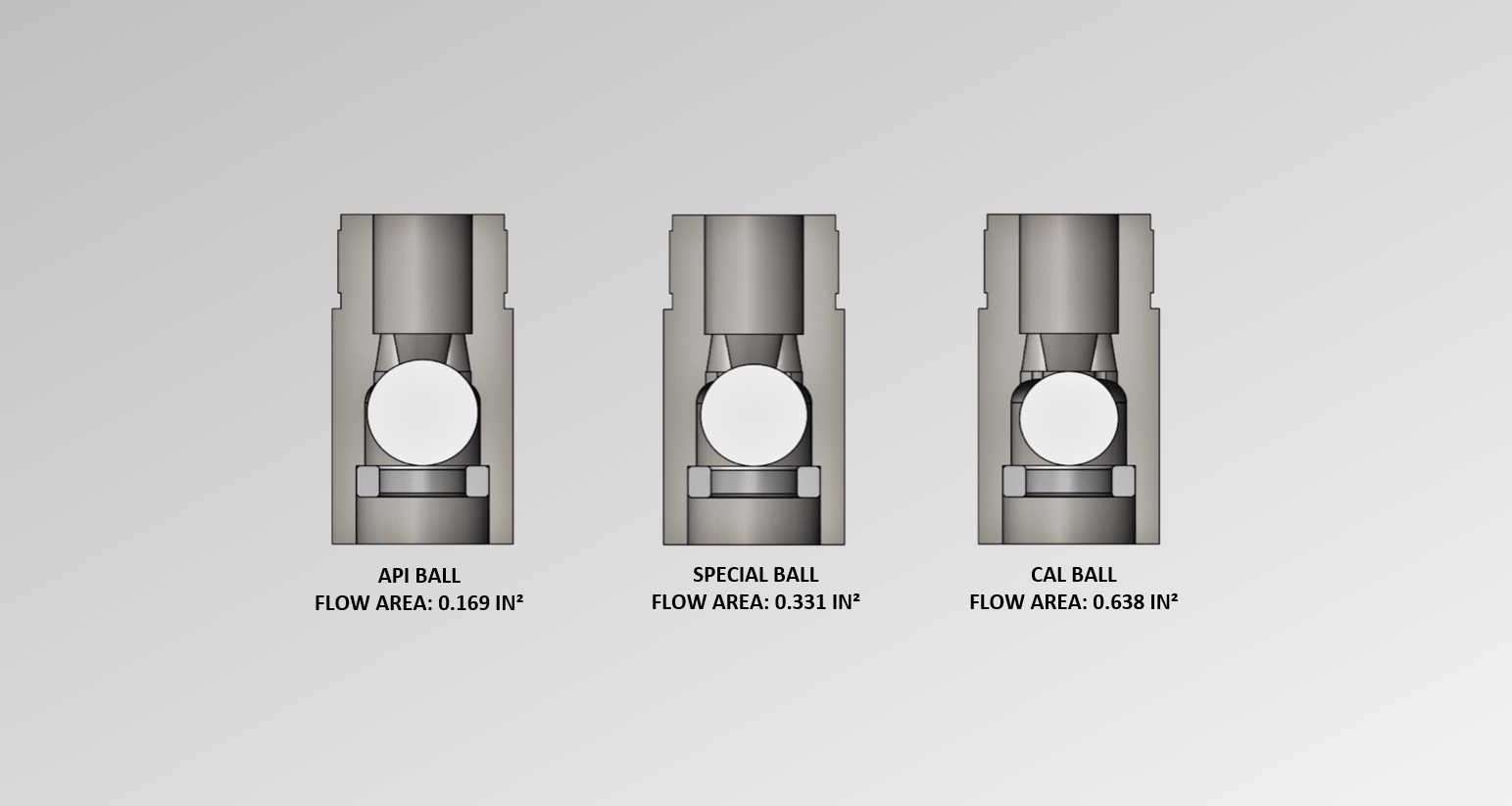

- Ball and Seat Design

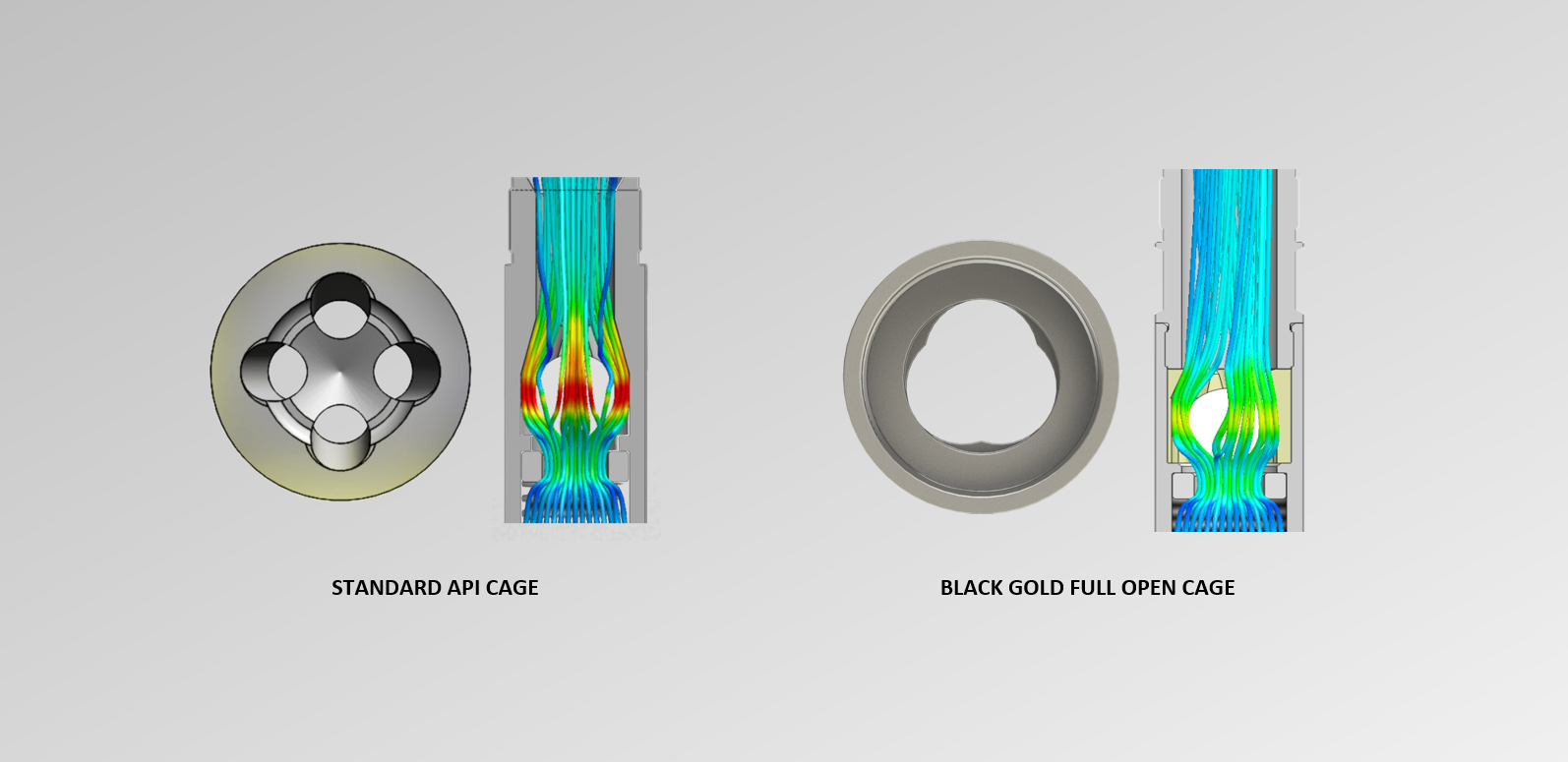

- Pump Cage Design

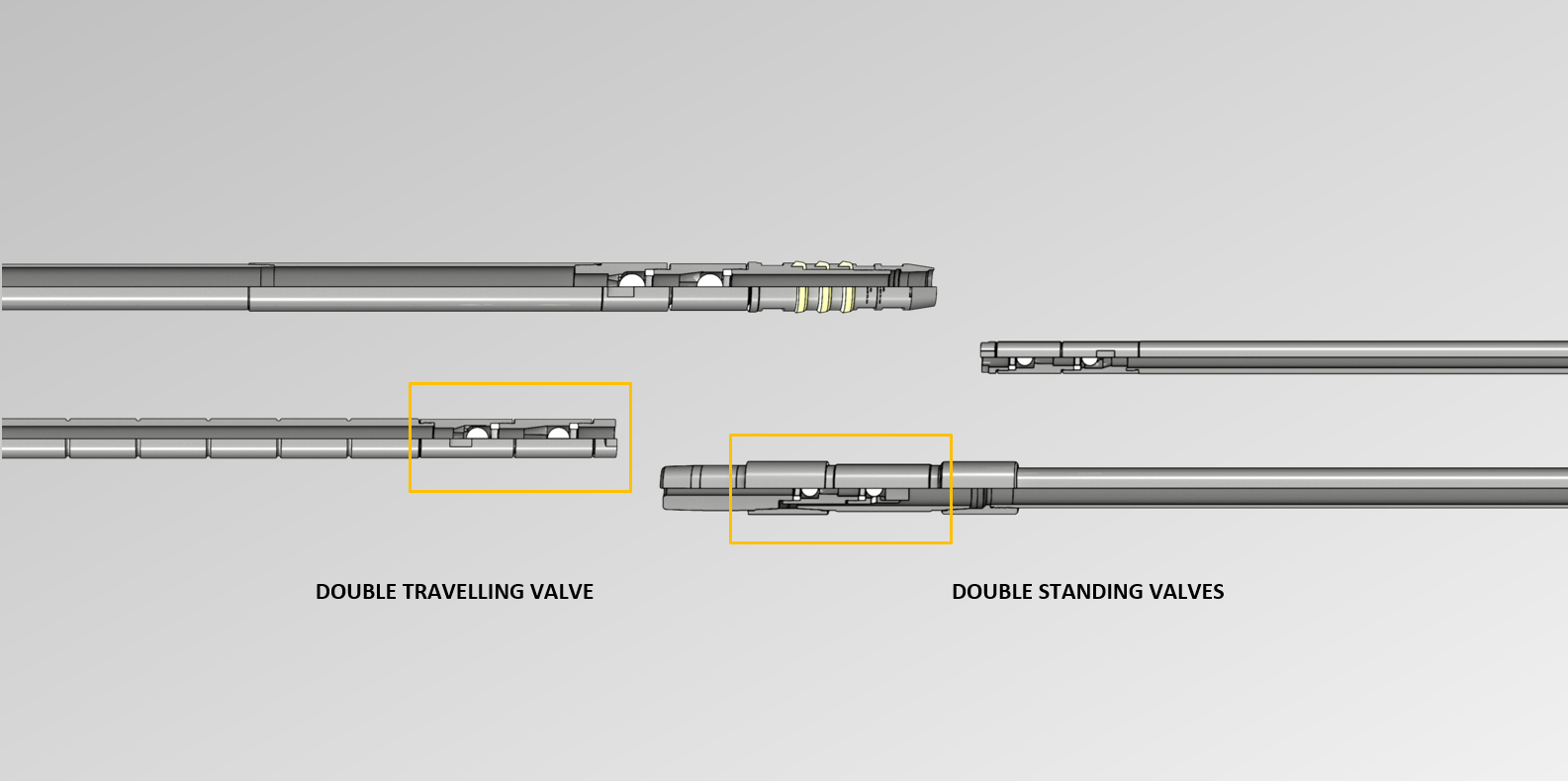

- Double Valve Cages

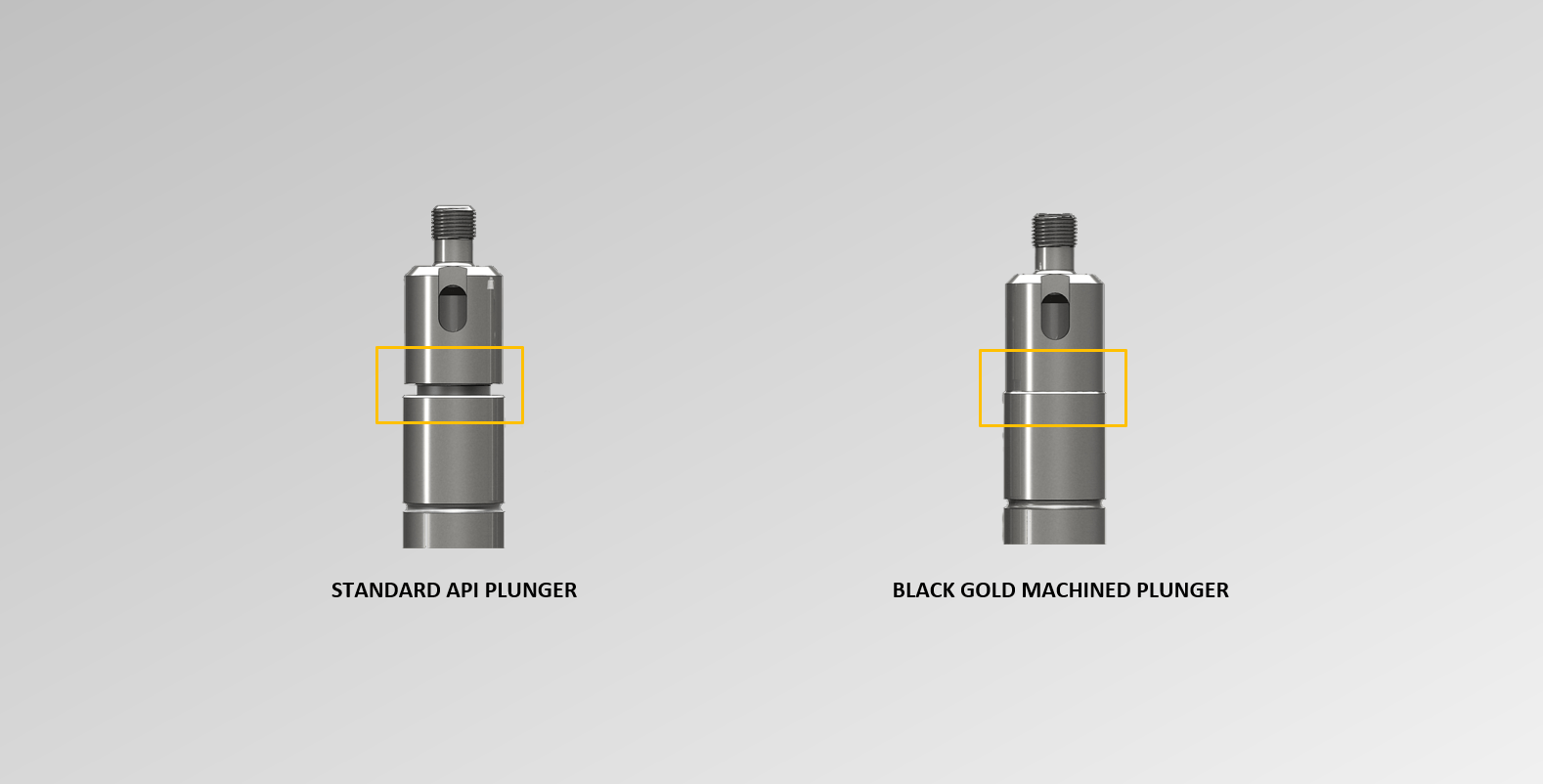

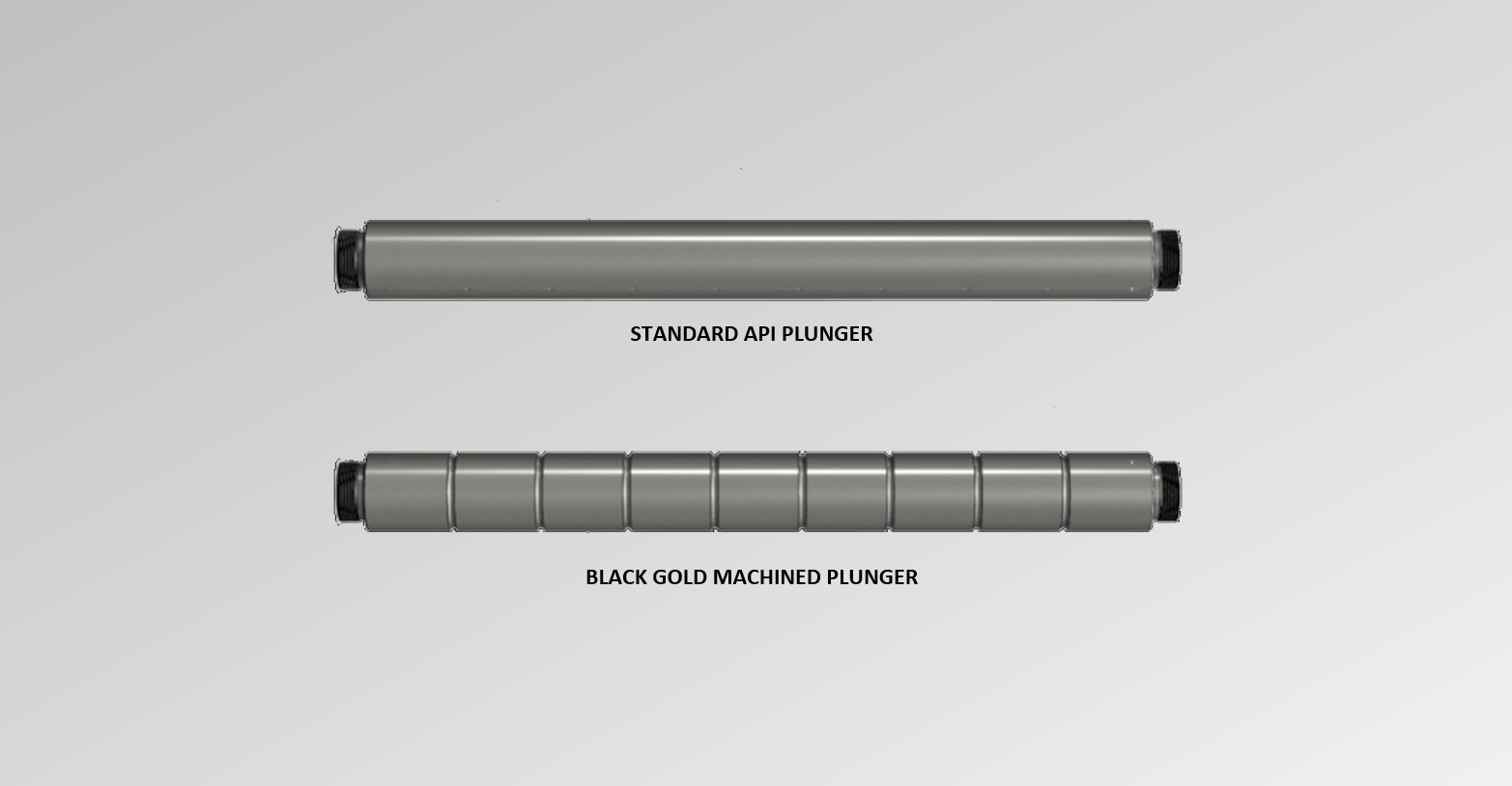

- Machined Plungers

- Grooved Plungers

- High Flow Barrel Connectors

Years of product research & developments had led to significant improvements to our pumps, these innovative designs are proprietary to Black Gold Pump & Supply Inc. and go above and beyond the standard API 11AX recommendation to exceed performance, reliability & durability.

These improvements enable our pumps to perform better than the standard API 11AX rod pumps the general market offers. Performance benefits include:

- Better solid handling

- Better gas handling

- Higher pump efficiencies

- Longer pump run life

- Reduced failure modes

- Reduced wear

Explore below the different technology that we have in placed to make this happen.

Need help selecting the right pump? We’re here to help!

Need help selecting the right pump? We’re here to help!

We want to know your needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.